Xa kuthelekiswa nezinye iintlobo zezinto zokwakha, i-steel gratings ineenzuzo zokugcina izinto, ukunciphisa utyalo-mali, ukwakhiwa okulula, ukugcina ixesha lokwakha, kunye nokuqina. Ushishino lwentsimbi luba yinxalenye ebalulekileyo yoshishino lwaseTshayina lwesakhiwo. Ukusetyenziswa kweentsimbi zensimbi kuya kuba yinto eqhelekileyo ekwakhiweni kwesakhiwo sensimbi. Indlela yokwandisa ubomi benkonzo ye-steel gratings kunye nokwandisa utyalo-mali kunye nesantya sokubuya sisihloko sophando kwiinkampani ezininzi. Makhe sithethe ngeengcebiso ezimbalwa ezichaphazela ubomi benkonzo ye-steel gratings.

Izinto eziphathekayo kunye nemveliso

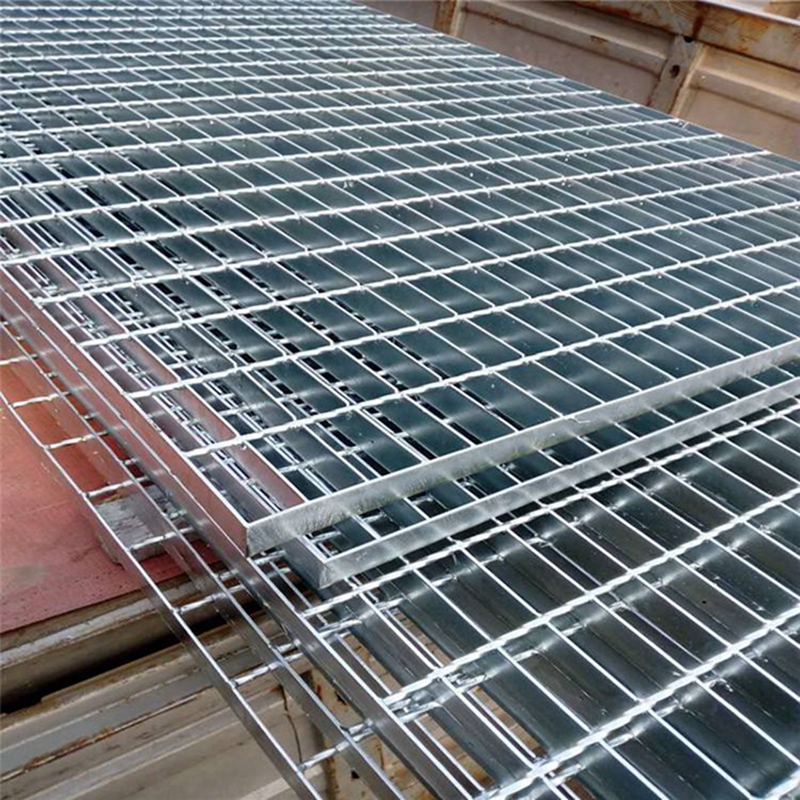

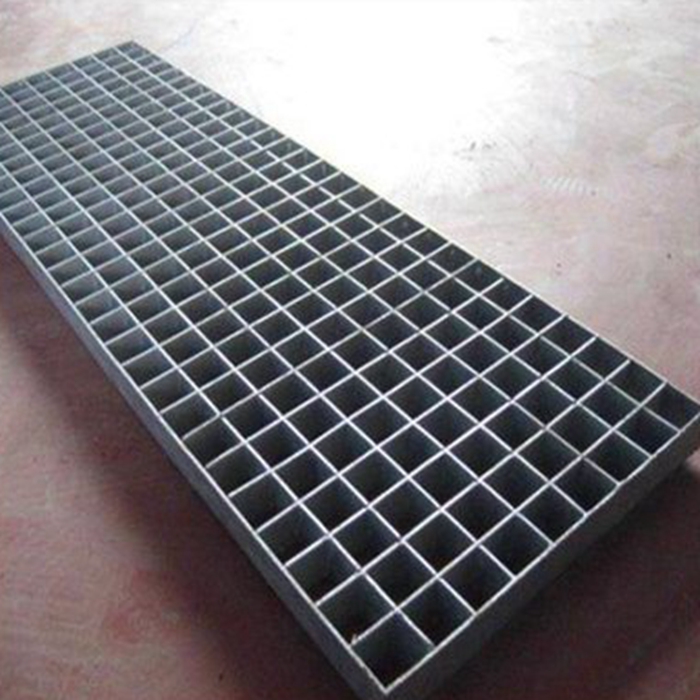

Ukubunjwa kweekhemikhali kunye neempawu zomatshini we-steel grating izinto eziluhlaza ziyimilinganiselo ebalulekileyo yokulinganisa umgangatho weentsimbi zensimbi. Kuphela izinto ezikrwada ezikumgangatho ophezulu zinokuvelisa iimveliso zentsimbi ezikumgangatho ophezulu. Ubomi bomgangatho ophezulu weemveliso zensimbi ziqinisekisiwe. Izinto eziphathekayo ze-steel grating izinto eziluhlaza yimeko ephambili yokuqinisekisa iimpawu zomatshini we-steel gratings. Iiparamitha ezahlukahlukeneyo zentsimbi yezinto eziluhlaza (izinto eziphathekayo, ububanzi, ubukhulu) kufuneka zilawulwe ngokungqongqo ukwenzela ukuba i-steel grating eveliswayo ibe nobomi obude. Inketho yokuqala yokuthengwa kwensimbi yensimbi yi-press-welded steel gratings. Intsimbi ecwebileyo yezinto ezixutywe ngentsimbi yensimbi ayinayo imingxuma yokubhoboza, umthamo wokuthwala umthwalo awunamandla, kwaye iimpawu zomatshini ziphezulu. Iigrayiti zentsimbi ezicinezelweyo zi-welded ngomatshini, kunye nokuhambelana okuhle kunye neewelds ezinamandla. Iigrayiti zentsimbi eziciniweyo zinomgangatho olungileyo kwaye kulula ukuzifaka. Iigridi zensimbi eziciniweyo zifakwe ngomatshini, kwaye akukho slag ye-welding, ezenza zibe zihle ngakumbi emva kwe-galvanizing. Ukusetyenziswa kwe-press-welded steel gratings kuqinisekiswe ngakumbi kunokuthenga i-gratings yensimbi eyenziweyo, kwaye ubomi benkonzo buya kuba bude.

Uyilo oluthwele umthwalo

Iimfuno zomthwalo we-steel gratings zicetywayo lisebe lokuyila kunye nomsebenzisi, okanye isebe loyilo kunye nomsebenzisi ukhethe ngokuthe ngqo ukucaciswa kweentsimbi zensimbi. Ukubalwa kobudlelwane phakathi komthwalo, ubude kunye nokuphambuka kwe-grating yensimbi kwenziwa ngokwemigaqo yokubala kwesakhiwo sensimbi. Uyilo lomthwalo we-steel grating lufuna ukuba ukuba kukho ukunqunyulwa kwi-grating yensimbi, indawo eseleyo ye-steel grating kufuneka ikwazi ukuhlangabezana neemfuno zomthwalo woyilo. Ukusetyenziswa kwexesha elide kubangela ukuba ukucaciswa kwe-grating yensimbi kutshintshe, okubangelwa ukungonelanga komthamo wokuzala. Ngoko ke, i-steel grating akufanele ilayishwe kakhulu. Ukuba i-overloaded, i-grating yensimbi iya kuphazamiseka, kwaye kwiimeko ezinzima, iya kufakwa i-welded okanye yonakaliswe, ichaphazela kakhulu ubomi bentsimbi yensimbi. Ukuze wenze i-steel grating ihlale ixesha elide, umda wokuthwala umthwalo kufuneka uqulunqwe ngokwendawo yokusetyenziswa ngexesha loyilo kunye nokuthenga ukuqinisekisa ubomi benkonzo yensimbi yensimbi.

Umhlwa wangaphandle

Ngenxa yokukhukuliseka kwezinto zeekhemikhali kunye ne-electrochemical corrosion, i-cross-section ye-steel grating components iyancipha, ngoko ke kucetyiswa ukuba kusetyenziswe unyango olushushu lwe-galvanizing surface. Inkqubo yokuvelisa i-hot-dip galvanizing ye-steel grating yinkqubo yomzimba kunye neekhemikhali apho i-steel ephathwayo ye-grating plated parts intywiliselwa kulwelo lwe-zinc olutyhidiweyo ukwenza umaleko owenziwe nge-galvanized kunye ne-alloy layer kunye ne-intermelting layer kwi-metal surface ye-steel grating. Yinkqubo yezoqoqosho kunye nesebenzayo yokukhusela izinto ezibonakalayo ezivunyiweyo ngamazwe ehlabathini lonke. Ubunzima kunye neemfuno emva kwe-galvanizing kufuneka zihambelane nemimiselo ye-GB/T13912-2002. Unyango lokutshisa i-galvanizing kwi-surface ye-steel grating inokunyusa ubomi be-steel grating.

Ulondolozo lwemihla ngemihla

Ingabonwa ukuba kukho izinto ezininzi ezichaphazela ubomi benkonzo ye-steel grating. Ukuba ufuna ukwandisa ubomi benkonzo yemveliso, kufuneka ubeke ingqalelo kumsebenzi wokulondoloza. Ukugcinwa kwemihla ngemihla kunokwenza i-steel grating ihlale ixesha elide.

Ixesha lokuposa: Jun-21-2024